Created at 09 June 2025

In supply chain management, understanding the difference between lead time and cycle time is crucial for optimising operations and meeting customer expectations. Although these two metrics may seem similar, they highlight different aspects of the supply chain process. This article explains their definitions, key differences, and why both are essential for operational efficiency.

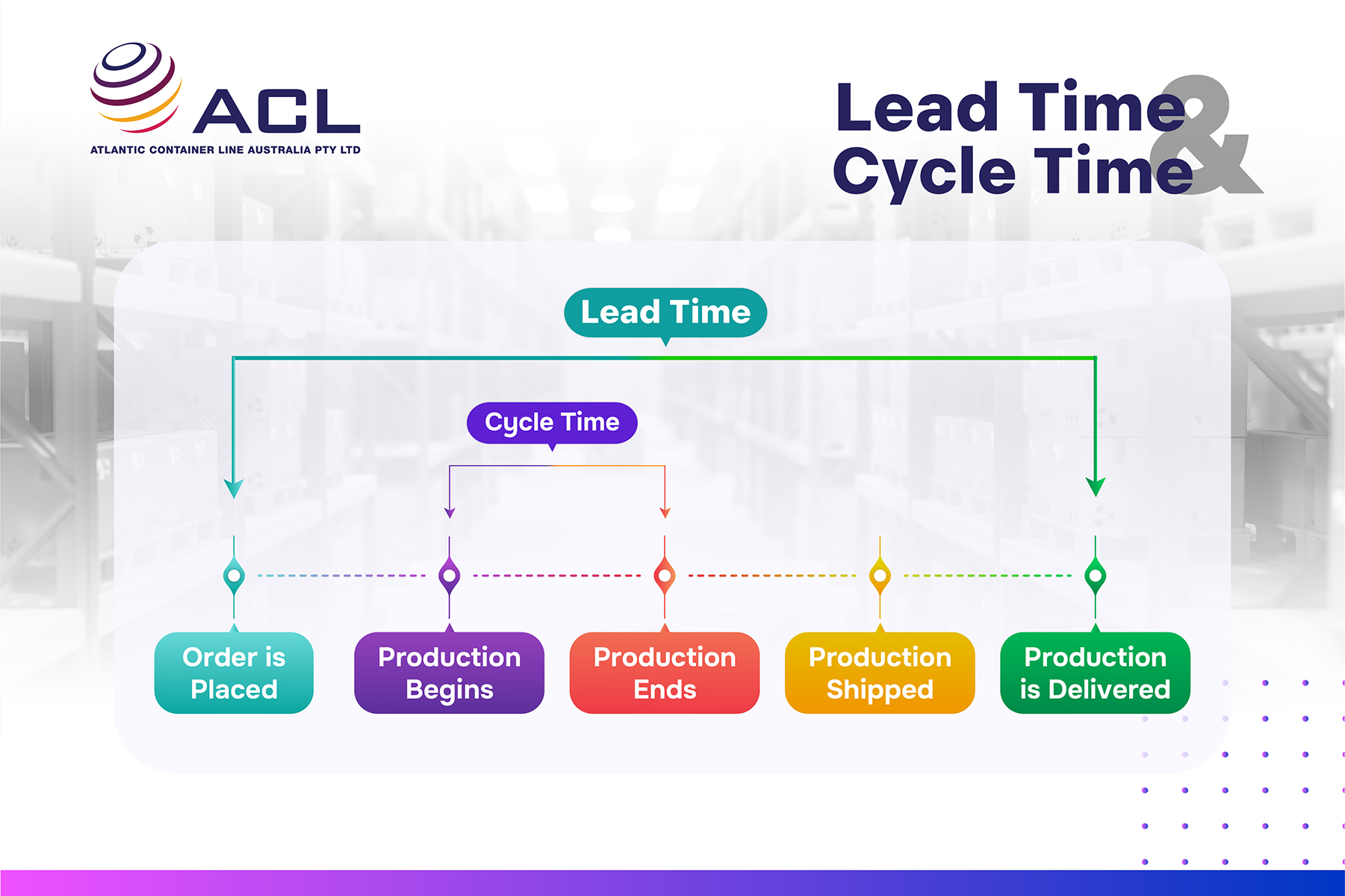

Lead time refers to the total duration required for a product to move from when an order is placed until the product is delivered to customers. It encompasses all supply chain stages, including order processing, manufacturing, transportation and delivery. Lead time is a crucial supply chain metric as it indicates how fast a business fulfils customers' demand. A longer lead time has an impact on the risk of losing customers due to slow order fulfillment. Slow order fulfillment refers to the delay between order placement and product delivery. Therefore, it is important to choose the right 3PL who understands the criticality of lead time for inventory management, meeting customer expectations and optimising logistics operations.

Cycle time refers to measuring the amount of time taken to complete specific tasks within the supply chain. In this case, the time that it takes to pick a product inventory or pack the product for shipping. Cycle time depends on factors including production speed, product quality, workforce productivity and bottlenecks in the process. Reducing cycle times is crucial for improving efficiency, reducing costs and enhancing customer satisfaction.

There are key differences between lead time and cycle time in supply chain:

Lead time focuses on the entire supply chain from order placement to delivery, while cycle time focuses the time required to complete a single process within the supply chain.

Lead time emphasizes speed of order fulfillment and customer satisfaction, while cycle time is used to improve efficiency within a specific process.

| Feature | Lead Time | Cycle Time |

| Scope | Entire process from order to delivery | Specific tasks within the supply chain |

| Focus | Customer fulfillment and delivery speed | Internal process efficiency |

| Impact | Affects customer satisfaction and demand | Affects cost control and productivity |

Understanding and improving both lead time and cycle time allows businesses to:

Enhance operational performance

Reduce supply chain costs

Meet or exceed customer expectations

Improve flexibility and responsiveness to market changes

--

Understanding the difference between lead time and cycle time is essential for businesses aiming to optimise their supply chain operations. By improving both metrics, companies can boost operational performance, reduce costs and increase customer satisfaction. Partnering with a reliable 3PL provider will be the right choice to help business streamline supply chain operations. Partnering with a reliable 3PL provider is essential for optimising these metrics. At ACL Australia, we help businesses reduce both lead and cycle times to enhance overall supply chain performance and customer satisfaction.