Created at 02 June 2025

Logistics and supply chain is moving at a rapid pace with the increase in demand and customer expectations to receive products and goods with shorter lead time. Efficiency is key in ensuring goods are dispatched on time from warehouse. Cross-docking is a logistics practice where inbound goods are directly transferred from the receiving area to the shipping area without intermediate storage. Adopting cross-docking practices helps to reduce costs, the need of storage space and ensure timely delivery to customer. In this article, we will explore cross-docking types, how it works and the advantages of using cross-docking.

Cross-docking is designed for high-volume products, perishable goods and other products that must be shipped immediately upon receiving at a warehouse facility. The process of cross-docking has benefits in optimising supply chain operation and improving efficiency. Cross docking is divided into two categories namely pre-distribution and post-distribution.

Pre-distribution cross docking

A supplier may have single or multiple customers for a product being received at a warehouse facility. These goods could be local or from overseas. When the goods arrive at the facility, it is then sorted immediately and staged for dispatch to the intended customers. Through pre-distribution cross docking, supplier could directly allocate all goods in a particular order to be directly dispatched without the need of it being stored beforehand. The processes involved in this activity are receiving, unloading, sorting and repackaging of goods based on predetermined instructions.

Post distribution cross docking

At times, a supplier could be shipping an order into a warehouse and require a short storage period before the item is re-routed to the final destinations of these goods. The final destinations of goods are only determined after they arrive at the cross-docking facility. It is stored temporarily until then. This is suitable for businesses which require inventory based on market conditions and sales data. This allows a more efficient and effective distribution depending on seasonal demands and market conditions.

There are several cross-docking methods. Each of these methods fulfill different needs.

Continuous cross docking

Continuous cross docking is a streamline process which involves transferring goods from inbound to outbound transportation with minimal storage time. It is a form of pre-distribution category of cross docking. This method is ideal for high demand products and perishable goods. Adapt to this method requires a high level of coordination among suppliers, carriers and the company operating a cross-dock facility.

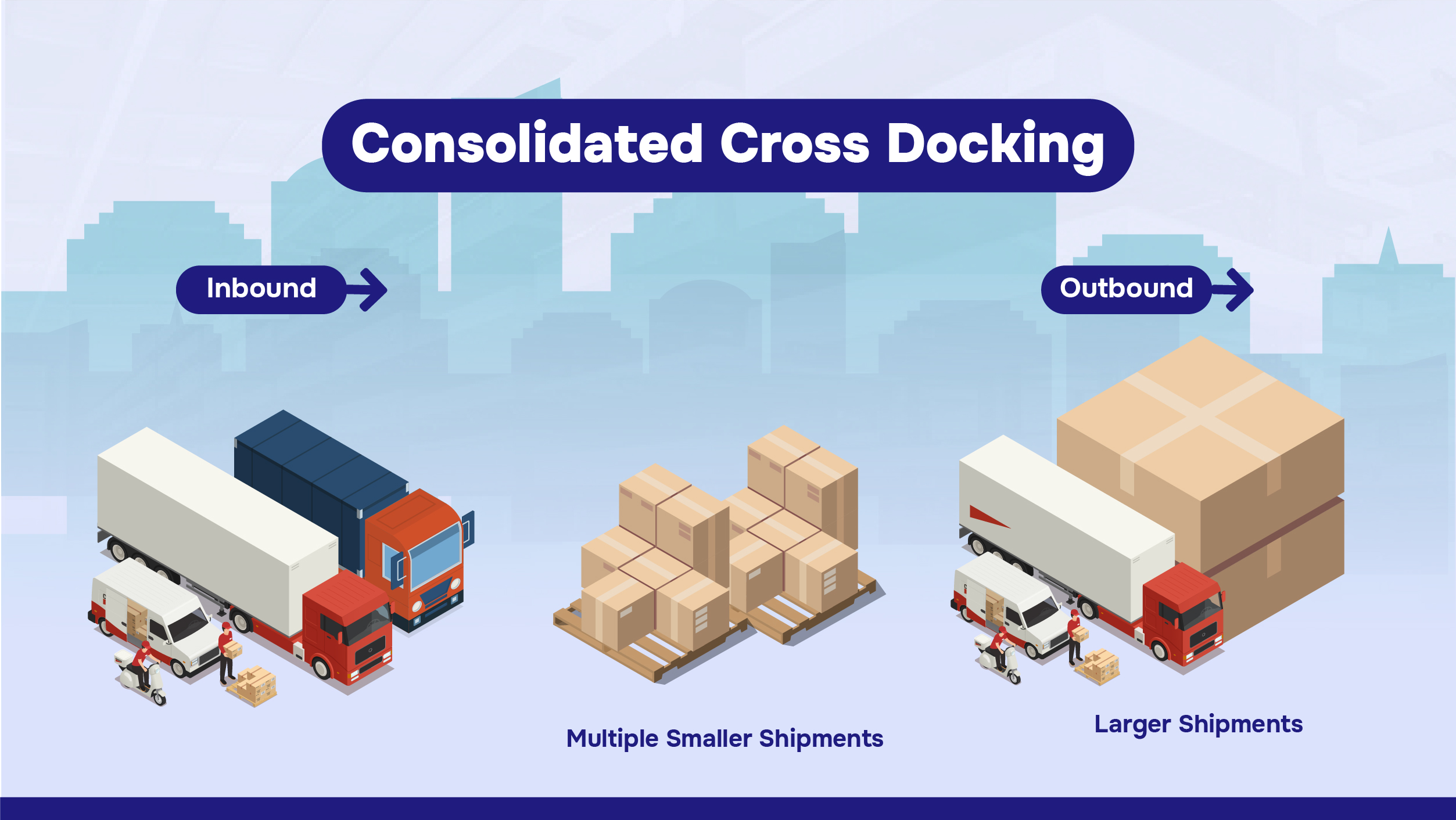

Consolidation cross docking

Consolidation cross docking involves combining multiple smaller shipments at a cross-docking facility to create one larger outbound load. It is a form of post distribution category of cross docking. This method requires goods to be efficiently warehoused at the facility then consolidating goods with other shipments destined for the same area and shipping the goods as full truckloads. The goal is to reduce transportation costs by optimising load capacity.

Deconsolidation cross docking

Deconsolidation cross docking is the opposite of the consolidation; this method involves breaking down large shipments into multiple smaller shipments. In this case, parcel carriers move goods across the country in a large shipment and split the shipment into smaller load for delivery to end customers.

Cross docking helps businesses to optimise the supply chain by reducing the storage costs, handling and transporting inventory. Examples of advantages of using cross docking are

Faster shipping

Cross docking ensures quicker delivery of goods without the need for long term storage. This process is suitable for time sensitive goods like perishable goods.

Cost and time savings

Businesses do not need to spend on storage, transportation and labor costs beyond the initial receiving and dispatching as items do not require storage and other maintenance.

Preventing product damage

In cross docking, perishable goods are not stored or only stored shortly in the warehouse. This will minimise spoilage and damage.

Cross docking is designed for customers which require goods to be dispatched directly or stored only for a short time in the warehouse. This ensures end customers receive products in a timely manner. At ACL Australia, we are ready to optimise supply chain through warehouse services include cross docking. Contact ACL Australia today to discover how our cross-docking solutions can streamline your supply chain and reduce operational costs.